About us

Our offer of exhaust and industrial smoke treatment becomes Poujoulat Heating & Power by Beirens, N°1 in Europe for the integration of turnkey exhaust systems in industrial process, district heating and electricity production.

Company

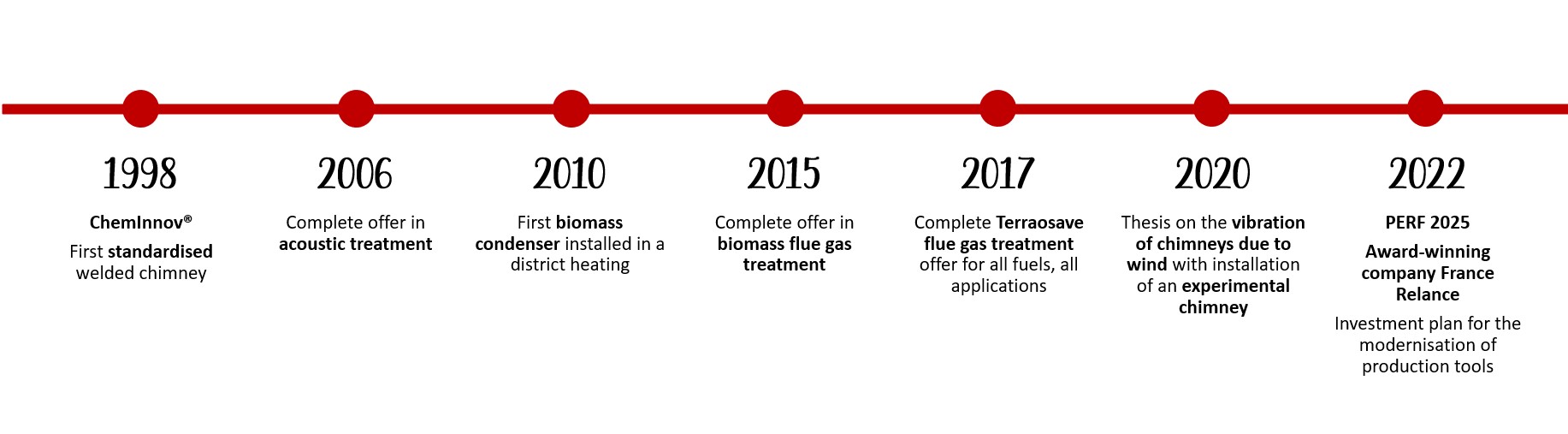

For more than 40 years, we have been integrating turnkey industrial exhaust solutions in France and around the world. Since 2010, we are one of the precursors of decarbonation in France: we filter and recover the industrial fumes and steams which are historically rejected in the atmosphere. Our offer is now stamped Poujoulat Heating & Power.

We are committed to putting people at the centre of our concerns. Thus, numerous training courses are organised each year for our employees in order to perpetuate our recognised know-how. Recent investments in production facilities have also strengthened our leadership position, while improving the comfort and well-being of our employees.

Aware of the current climate and environmental issues, BEIRENS is keen to support projects with the lowest possible carbon footprint.

With an international organisation, Poujoulat Heating & Power offers solutions and associated services throughout the world and in all sectors of activity. We currently have more than 30,000 references around the world.

Production tools

Located in the centre of the Centre-Val de Loire region, in Buzançais, Poujoulat Heating & Power by Beirens has a production facility covering an area of 42,000 m². One of the largest industrial exhaust production plants in Europe, we ensure the in-line production of industrial chimneys, ducts, silencers, condensers/washers, on 100-metre-long bays. From preparation to finishing, our team uses modern equipment to ensure safety and quality at all stages of production.

Every year, Poujoulat Heating & Power by Beirens devotes a significant budget to the acquisition of modern equipment. The launch of the PERF2025 project aims to increase the production capacity, to improve the skills of the teams and to train new employees.

Research & development

BEIRENS’ technological advances are based on our Research & Development and Quality Safety Environment departments, as well as on the skills of the CÉRIC laboratory, CETIM, and partner laboratories specialising in gas dynamics, structural vibration and acoustics.

The CERIC laboratory, with its 30 years of expertise, is the reference laboratory in Europe in the fields of chimney and sustainable energy. COFRAC accredited, CERIC carries out tests on fuels and combustion, as well as tests on the coupling of the “appliance – fuel – flue system”. Our research focuses on energy efficiency and the reduction of polluting emissions.

The CERIC laboratory benefits from considerable equipment: 550 m² of available surface area with a biomass boiler room. Six test halls: mechanical, thermal, aeraulic and combustion. More than 4,000 tests are carried out each year as part of the quality control and continuous improvement of the group’s products.

Quality safety & environment

Developing innovative solutions

Our Quality, Safety and Environment department is continuously working on the implementation of new safety certifications for all products and services. The BEIRENS production site is ISO 9001 certified and the products manufactured comply with the CE standards in force.

Reducing environmental impact

As a member of the Syndicat des Énergies Renouvelables and the Comité Interprofessionnel du Bois Energie, BEIRENS is committed to reducing its environmental impact: waste recovery, recycling, recovery of plastics, metals, cardboard, paper and wood. In a desire to reduce its carbon footprint, the site is heated by a biomass boiler and LED lighting is used.

Preventing risks

Safety at work concerns us all and is monitored on a daily basis by the Quality Safety Environment department. Several areas of development have been established to limit the risk of accidents on the site as much as possible: weekly newsletter to inform and remind employees of safety rules, zero accident plan.

Training

In order to respond to changes in standards, legislation and techniques, BEIRENS develops a vast training programme for all its employees every year.

In partnership with professional training organisations such as AFPI, AFPA, GRETA and the Chamber of Commerce of the Indre department and Industry, BEIRENS has the necessary skills to master the rules of the profession. BEIRENS also has its own training school.

The BEIRENS training plan is based on 3 main areas:

- “workshop” training: training for overhead cranes, forklift trucks, welding, etc.

- “site” training: training in driving site machinery, chemical risk prevention, scaffolding, working at heights, first aid at work, etc.

- “profession” training: training in business knowledge, generators, standards and regulations, etc.

BEIRENS has always supported the apprenticeship for training its future employees. Many workshop managers, welders, boilermakers, IT specialists, sales people and project managers have benefited from this option during their training for a diploma. In fact, more than 40 apprentices have been trained.